In technical diving, few debates get as heated as backmount versus sidemount. Both systems have their place, and both can be configured safely and effectively in the right context. Yet, discussions often become emotional or trend-driven rather than focused on function, efficiency, and the realities of underwater procedures.

To understand which configuration is more appropriate, it’s important to separate form from function and revisit the fundamental principles that define technical diving: control, practicality, predictability, and standardization.

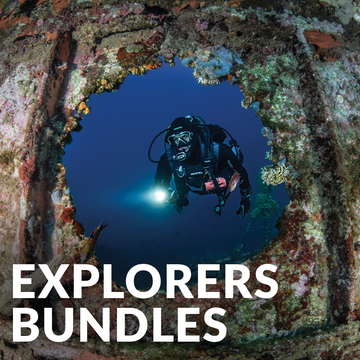

The Origins of Sidemount: A Tool for Exploration, Not a Universal Solution

Sidemount was originally developed for highly specialized cave exploration, particularly in systems with narrow restrictions where backmounted doubles physically could not fit. In that environment, sidemount cylinders allowed divers to unclip and push tanks ahead through tight spaces — a practical solution for a specific problem.

Over time, sidemount expanded beyond its roots. Many divers adopted it for open-water diving, drawn by perceived comfort, gear flexibility, or aesthetic appeal — it simply looks “techy” and “cool.” For divers with physical limitations such as back or shoulder injuries, sidemount can indeed be a practical choice. However, when it comes to technical diving — where precision and efficient gas management are paramount — sidemount introduces complications that must be understood.

Understanding the Backmount Manifold System

Backmounted doubles with a manifold and isolator valve form the cornerstone of standardized technical diving systems, particularly within the DIR framework. The manifold links both cylinders into a single gas system, allowing access to all gas from either regulator. This setup provides redundancy and flexibility — the fundamental safety pillars of technical diving.

The configuration consists of:

- Two independent regulators (one per post)

- Two valves (left and right posts)

- A central isolator connecting both tanks

Why the Manifold and Isolator Matter

- If a right-post regulator fails, you can shut down that post and still breathe from the left — with gas from both tanks available through the isolator.

- If a left-post regulator or valve fails, the same principle applies: isolate the problem and continue breathing safely from the working side.

- Only if the isolator itself fails (a rare event) will you lose access to one side’s gas. In that case, the unaffected cylinder must be protected by closing the isolator.

But which side of gas will you lose? Most likely the left one — but it depends.

Inside the crossbar, there’s an internal passage (bore) that allows gas to flow between the two tanks when the isolator is open. The isolator knob operates a stem with a sealing seat — turning it opens or closes this passage. If the isolator itself leaks, gas will escape from one side of the manifold depending on the orientation of that seat and stem.

- The seat and O-ring seal the gas flow.

- The seat is physically located closer to one side — left or right — depending on how the manifold was manufactured or assembled.

- If that O-ring fails, gas will escape from the same side as the seat, even if you close the isolator.

Most modern manifolds (Halcyon, Dive Rite, Apeks, etc.) are left-seated, meaning if your isolator fails and you close it, you’ll likely lose gas from the left cylinder.

However, this is not universal. Some older or non-standard manifolds are right-seated, so it’s essential to know your manifold’s configuration.

As mentioned above, isolator failures are rare — meaning that under almost all foreseeable circumstances, a backmounted diver can retain access to nearly 100% of their usable gas even after a critical equipment failure.

Sidemount Redundancy: Independent but Limited

Sidemount achieves redundancy differently. Each cylinder is completely independent, with its own valve, first stage, and second stage. While this provides physical redundancy, it also isolates gas supplies. A failure on one side means all gas in that cylinder is inaccessible until the problem is resolved.

Because both cylinders are separate, the diver must manually balance gas consumption by alternating between regulators at regular intervals. This adds constant task loading and cognitive demand, which can become problematic during complex or high-stress dives.

While sidemount divers benefit from excellent valve accessibility and visual confirmation of leaks, the lack of a manifold introduces operational complexity in gas tracking and emergency handling.

Gas Management and Failure Handling

Gas management is at the core of technical diving safety. Backmount doubles simplify this process by allowing both regulators to draw from the same unified gas source. The diver doesn’t need to switch regulators mid-dive or manually track two separate consumption rates.

In the event of a malfunction, a diver performs a valve drill — a standardized, repeatable sequence to isolate the problem side while maintaining control of remaining gas. This system enables fast, efficient, and consistent responses, even under stress.

In sidemount, the diver must diagnose the issue, close the affected valve, and often loses access to that cylinder’s gas entirely. Though manageable by a skilled sidemount diver, this process increases stress and task load during emergencies.

Valve Accessibility and Diagnostics

Here, sidemount holds a clear advantage. With cylinders mounted at the diver’s sides, valves are fully visible and easy to reach. Any leaks or bubbles are immediately identified, and shutdowns can be performed quickly and precisely.

Backmount divers, on the other hand, rely on tactile and auditory feedback — locating leaks by sound and touch during valve drills. This requires consistent practice and flexibility but, when mastered, is highly reliable. The difference lies in visibility versus practicality: sidemount lets you see the problem, while backmount gives you a more efficient way to solve it.

Efficiency and Team Standardization

Technical diving is rarely a solo pursuit. Teams rely on shared procedures, predictable configurations, and mutual assistance. This is where backmount demonstrates a clear operational advantage.

Backmount doubles are simple to assemble, easy to standardize, and universally recognized. Every team member knows where each valve, hose, and regulator is located — allowing immediate and intuitive responses to any issue.

Sidemount, by contrast, is inherently individualized. Different harnesses, hose routings, and switching protocols mean every sidemount diver’s setup can function slightly differently. In a team setting, that variability complicates coordination — especially during stress events when clarity and consistency matter most.

Practicality and the Challenge of Multi-Cylinder Sidemount Diving

Sidemount works elegantly with two primary cylinders, but its practicality decreases as dive complexity increases — particularly for deep trimix or multi-stage decompression dives. Managing four, five, or even six cylinders clipped along the body becomes cumbersome. Gas switches must be performed with precision to avoid entanglement or confusion.

Each cylinder must be tracked, switched, and secured independently. With multiple gases (travel, bottom, deco), the diver must perform numerous regulator swaps and label checks — all while maintaining awareness. This significantly increases cognitive load in challenging conditions like cold water, current, or low visibility.

On the surface, handling and preparing multiple sidemount cylinders is also more cumbersome. For both shore and boat diving, managing six separate tanks is far more demanding than assembling one backmount set with clipped stages.

When Sidemount Makes Sense

Sidemount’s strengths are situational. It excels in:

- Tight cave or wreck penetrations where backmount cannot pass

- Remote sites requiring long surface carries or difficult shore entries

- Divers with medical or mobility limitations

In these cases, sidemount’s modularity and accessibility make it an invaluable tool. But outside of these specialized missions, backmount remains the simpler, safer, and more efficient system for the majority of technical dives.

Conclusion: Choosing the Right Tool for the Mission

Both backmount and sidemount are valid technical configurations — but each was designed for a distinct purpose. The backmount manifold system offers unmatched efficiency, redundancy, and team compatibility, making it the gold standard for most open-water, wreck, and deep trimix dives.

Sidemount remains invaluable for specialized exploration where mobility and access take priority. Ultimately, the choice of configuration should be driven not by trends or aesthetics, but by function, environment, and the diver’s ability to maintain control under stress.